- #Solid edge cad management update

- #Solid edge cad management manual

- #Solid edge cad management software

So, today, anyone who saves a drawing, indexes it, and creates a corresponding BOM is already no longer engaging in CAD data management in the narrow, historical sense of the term (because all that means is storing drawings with references to its parts). The error rate goes down, time and resources can be better spent elsewhere, and it becomes that much easier to handle product data and the information it conveys.

#Solid edge cad management manual

It creates a network of knowledge that is readily available without any manual effort. Regardless of their size or industry, companies simply cannot afford to not address these demands of digitalization.įor this very reason, the purpose of a modern CAD data management system is to create references and links between all the different pieces of information needed to describe a product, also known as as dependency knowledge. CAD data management systems need to make their information available and reusable to ensure it is immediately actionable for other systems without prior human intervention. The only way to do that is through true end-to-end digital transformation.

#Solid edge cad management software

Mechanical drawings, however, are nowhere near enough to describe a product: mechatronic components, software (whose share in products is ever increasing), instruction manuals, and other accompanying documents serve as additional information carriers. The drawing numbers, part descriptions, change status, or material ID that CAD designers need are stored in a database and made available for research and change processes.

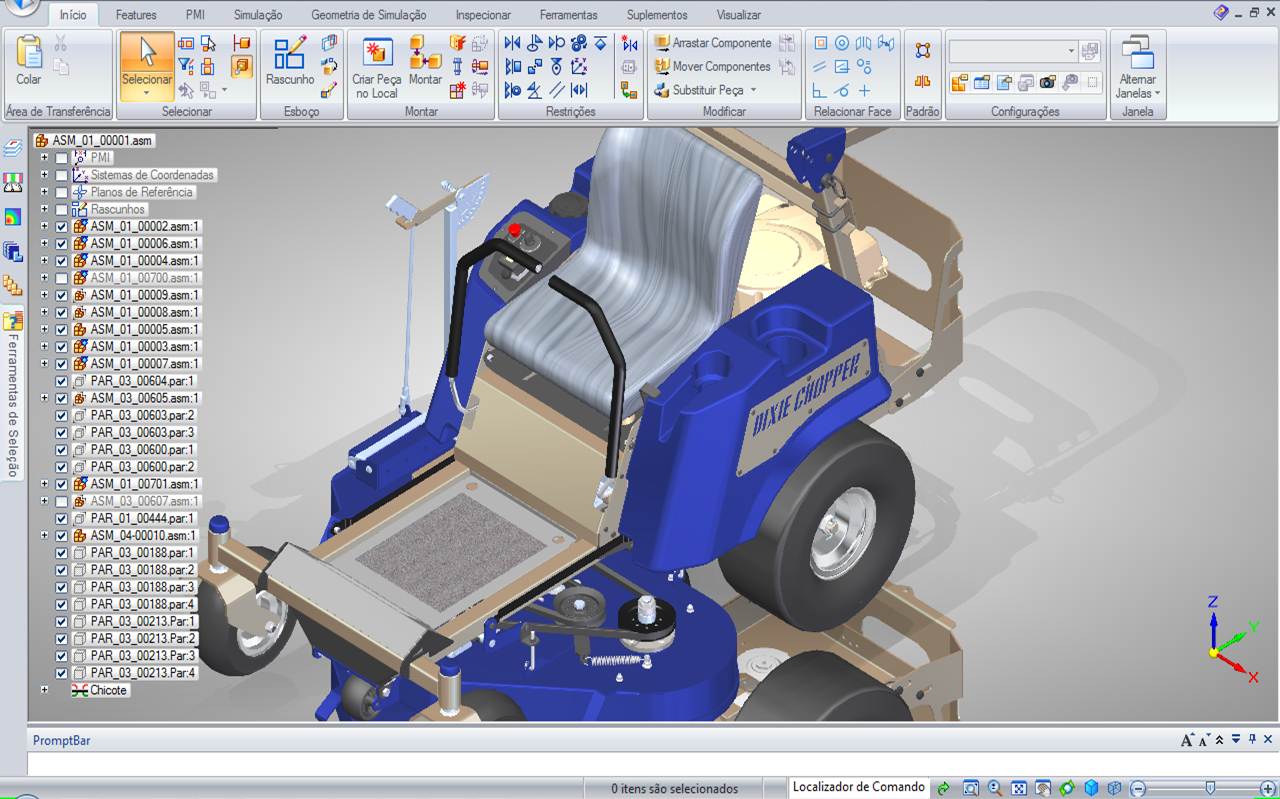

Many CAD systems still come with more or less rudimentary features that allow us to store and retrieve CAD data. If you need to improve your data management for Solid Edge, why not read more about DDM CAD today? Or simply get in touch with our team for more information.The advent of CAD systems such as AutoCAD, Autodesk Inventor, Creo, Solid Edge, NX or SolidWorks enabled users to create their technical drawings electronically, which consequently meant that they had to find a way to manage these drawings and the information that went along with them. Our latest release includes many enhancements to make your life easier, together with 14 new features. When you choose our PDM system for Solid Edge, your designers can spend more time designing and less time searching for data. Simple to use and administer, it has been designed by CSI- a team of technical and business professionals who are committed to developing industry-leading design and PDM software solutions. This includes the automatic downstream of the BOM data to your MRP or ERP system along with global database replication.

#Solid edge cad management update

Highly affordable yet versatile and intuitive, our system has been know to reduce costs by up to 60% for customers who use Solid Edge, in comparison to other PLM systems.ĭDM CAD enables you to manage all types of data across your business, including enabling non-CAD users to view, store and update information. Whether you use Solid Edge, SolidWorks or Inventor to develop your products, our powerful system is used by companies all over the world. Ideal for both small businesses and large enterprises, DDM CAD can help you regain control over your data.

0 kommentar(er)

0 kommentar(er)